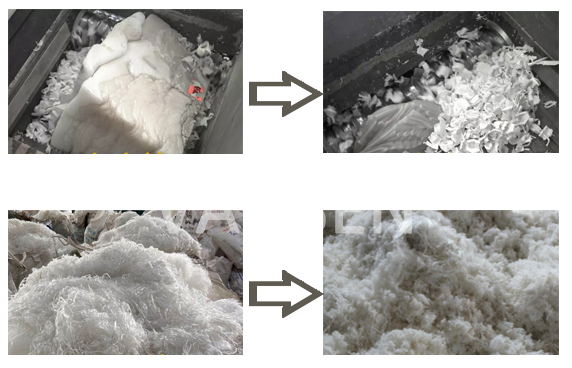

During the operation of the single axis shredder, the material is approached by the pressure plate near the moving blade. The alloy blade embedded on the blade repeatedly cuts the material to crush large pieces of material. The cut material is then cut through the mutual shear between the fixed blade and the moving blade to meet the crushing requirements. The crushed material is then filtered through the bottom screen of the equipment, thus completing the entire single axis shredder crushing process. Mainly used for crushing and processing various plastic injection molding machine materials, plastic pipes, plastic plates, plastic frames, plastic films, logs, waste furniture, and other materials.

Single shaft shredder machine is used in various industries of small and medium-sized materials refining and waste recycling, mainly dealing with high hardness, high toughness of rubber head material, plastic products, wood, industrial waste paper, etc., the particle size uniform after shredding is about 40mm. The single shaft shredder occupies a small area, is durable, and is used in various industries for material refinement and waste recycling.

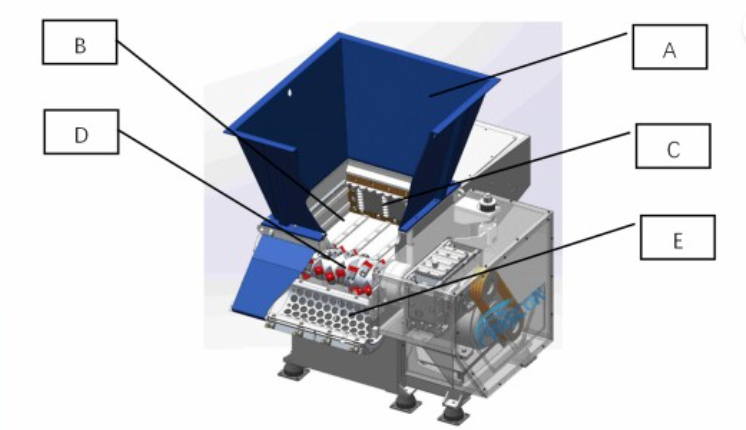

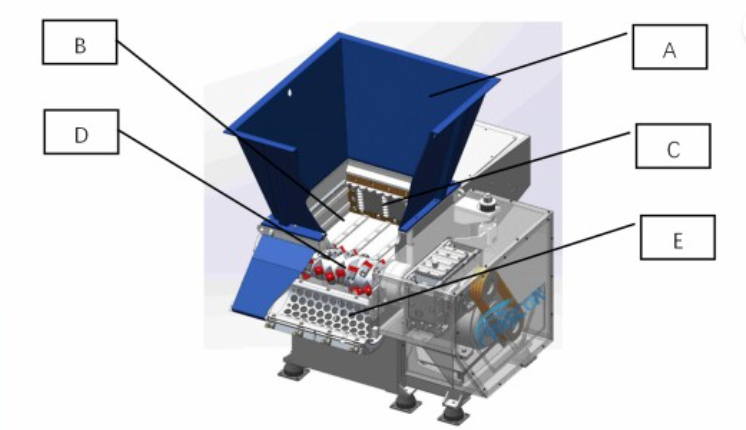

Single shaft shredding machine is mainly composed of blade spindle, fixed knife, bearing box, box support, feeding system, hydraulic pushing system, power system, electrical control system.

1. Single axis shredder, suitable for crushing solid materials that are difficult to break, such as rubber heads, thick plates, thick walled pipes, tree poles, thin film materials, and winding materials. It can also be used for general plastic shredding. 2. Choose different types of blade roller structures based on the materials to be processed, such as ordinary blade rollers, thin film blade rollers, hard material blade shafts, etc. After the blade is worn, it can be used in different directions. 3. The push box is hydraulically controlled to repeatedly push materials onto the blade shaft. 4. Multiple protection for machinery and electrical appliances, in accordance with CE standards. 5. Adopting hardened gearbox, safe and stable, with water cooling function. 6. The bearing is externally installed to effectively prevent dust from entering the bearing, and regular packing is set up. 7. The shredded materials can be directly recycled or can be re shredded by a paper shredder as needed.