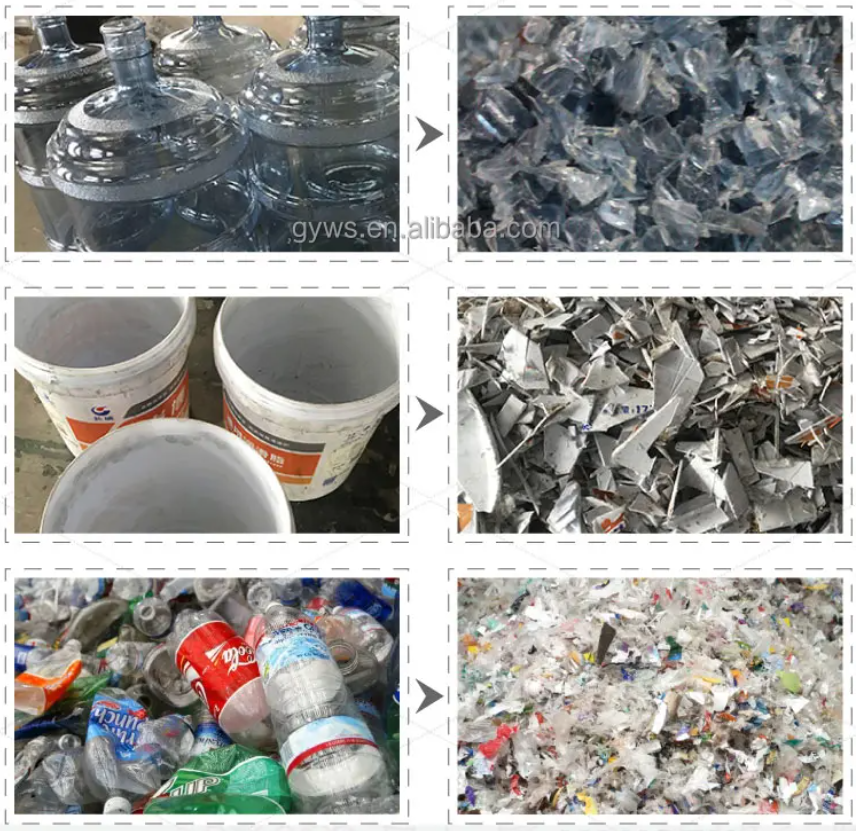

A dual axis shredder is a shredding device used to reduce the volume of solid waste, consisting of a knife chamber, a frame, and a conveyor. Its dual axes are independently driven. During the production process, the motor drives the spindle of the cutter chamber through a belt pulley, causing the cutter blades to rotate with the cutter seat body connected to the spindle, achieving the feeding function. The different soft and hard waste materials entering the cutting chamber are crushed through shearing, tearing, and squeezing between the blades, and then filtered through the bottom of the cutting chamber to allow the material to fall according to the required size. It is used to cut, shear, and extrude large pieces of material into small pieces, which is beneficial for material regeneration and recycling.

Double shaft shredder is a kind of machine used for material coarse crushing, generally used in the crushing or recycling and reuse industry for processing unprocessed raw materials or waste materials shredder through the power system to drive the spindle to drive the blades rotor rotation, through the blades and blades to cut each other, can shredder scrap metal, plastic, tires, furniture.

The shredder frame bo ard is thick and can withstand high torque, making it very sturdy. The shredder has a thick and heavy moving blade with high crushing power, and the cutting tools are all made of alloy steel casting, which is sturdy for use. The shredder adopts microcomputer (PC) automatic control, equipped with start, stop, reverse, and overload automatic reverse control functions. The thickness and number of claws of the shredder cutter can be changed according to different materials. The shredder equipment has the characteristics of low speed, high torque, low noise, and dust that can meet standards. The shredder is easy to adjust, has low maintenance costs, and is economical and durable.